Handling Mayo’s waste with pride, saving millions, protecting the environment in the process

Learn how three small teams in Rochester handle Mayo's waste with pride, saving the organization millions of dollars each year.

From sorting, shredding and baling to burning, neutralizing and educating. That's on the daily docket for three small teams in the Facilities Management Division of the Department of Facilities and Support Services at Mayo Clinic in Rochester.

The 30 colleagues who make up those teams are unsung heroes who expertly manage more than 60,000 pounds of waste Mayo produces daily. That includes solid waste, regulated medical waste, as well as hazardous and radioactive waste.

Guided and inspired by Mayo's value of stewardship, the teams are constantly working to reduce the environmental impact and maximize value in return.

The results are showing. Mayo's recycling efforts in Rochester alone have saved the organization almost $2 million this year. By efficiently burning permitted waste, Mayo also reduces the demand for landfill space for these waste streams by 90%. And Mayo manages nearly all of its radioactive waste internally, avoiding the high cost of vendor services.

The News Center team recently met with Wade Schwinefus, who manages the Waste Management Facility, Brian Tweite, who leads operations at the Recycling Center, and Ray Gladkowski, who heads up the hazardous and radioactive waste team to go behind the scenes in their areas.

Sorting, shredding and baling at Recycling Center

Everything you deposit in a recycling container across Mayo Clinic in Rochester and some locations at Mayo Clinic Health System in Southeast Minnesota — including soda cans, paper, plastic and batteries — will make its way to Mayo's Recycling Center, located on the East Lot downtown. That's also where Tweite's team of 12 workers receives food waste, electronics, scrap metal and about a dozen other materials.

Most materials are sorted by hand before they're processed for distribution to different vendors.

"That's why the cleaner the product we can get, the better, easier and safer it is for staff," Tweite says.

That's also a big reason why Camille Lunn is a critical member of the Waste Management team. Lunn is an education coordinator who teaches Mayo groups how and why to separate their waste materials properly.

"If you put a pop can into a paper receptacle and it makes its way into our paper shredder, it's going to ruin the shredder," she says.

And it's not just an aluminum can that can cause trouble. Tweite recalls how a small part from an artificial hip damaged the paper shredder.

"It was no bigger than the ball in a computer mouse, but it was made of titanium, so it ruined the teeth of the shredder, and we were down a week and a half," he says.

Watch this video to see how Brian Hess and Larry Paulson, both recycling processors, are preparing a fresh load of paper for shredding and baling.

The team works hard to ensure that recyclables are truly recycled and that processed materials stay in the area, whenever possible. While the bales of shredded paper go to paper mills in Wisconsin, the hundreds of styrofoam specimen containers that arrive at the Recycling Center daily are also shredded and turned into a log. A vendor later uses the material as padding in bicycle helmets.

At least a dozen vendors come to Mayo to pick up materials at the Recycling Center, including a pig farmer who comes twice a week to pick up food scraps collected from Mayo kitchens.

"Everything that goes in our building goes out again," Tweite says.

While some processed recyclables are sold to vendors, Mayo sometimes pays a fee.

"It's not about profit but cost avoidance," Tweite says, pointing to the almost $2 million savings this year.

He also credits his team for running a successful recycling operation.

"Our team is awesome. What they do on a daily basis with the huge amounts of materials coming in is incredible," Tweite says.

Clean burning at Waste Management Facility

While more than a third of Mayo's waste ends up at the Recycling Center to find a second life, Schwinefus and his team are taking care of most remaining waste at the Waste Management Facility near the Rochester International Airport.

That includes solid waste from offices or cafeterias, regulated medical waste from labs, patient rooms or surgeries, and low-level radioactive waste, all of which are prepared for burning.

After several truckloads of solid waste arrive at the facility multiple times a day, the piles are prepared to go on a conveyor belt.

Watch this video to see how Dave Mathis, Waste Management Facility operator, prepares a new load.

A new load of waste is dropped into a hopper before a quick journey on a conveyor belt, from where the waste is mechanically pushed through two combustion chambers, the last one reaching a temperature of 1,900 degrees. After about 10 hours of a slow and controlled burn, a comparatively small pile of ash remains.

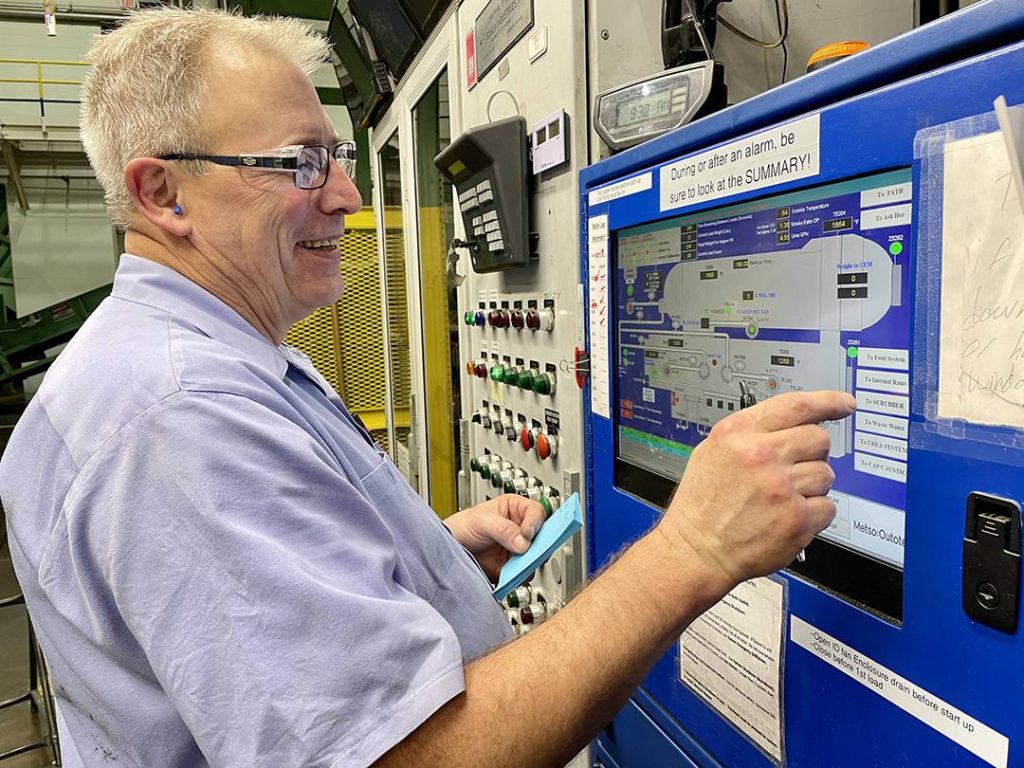

Schwinefus, who has worked at the facility since it was built in 1993, takes great pride in Mayo's emphasis on burning waste as clean as possible, thanks to two large scrubbers, which ensure that any harmful emissions are neutralized.

"We pass all our emissions with the first scrubber, but we decided to put in a second one because our limits are so low. We didn't need to put it in but wanted to have that assurance," Schwinefus says.

His team pays equal attention to the wastewater that catches the ashes, ensuring that any harmful materials are removed or neutralized before the water is recirculated.

"We want to make sure we do everything right for the environment and Mayo," Schwinefus says.

Special process for hazardous, radioactive waste

Ray Gladkowski and his hazardous and radioactive waste team perhaps have the most trying of all waste-related jobs.

"We deal with all the stuff no one else wants to deal with," Gladkowski says.

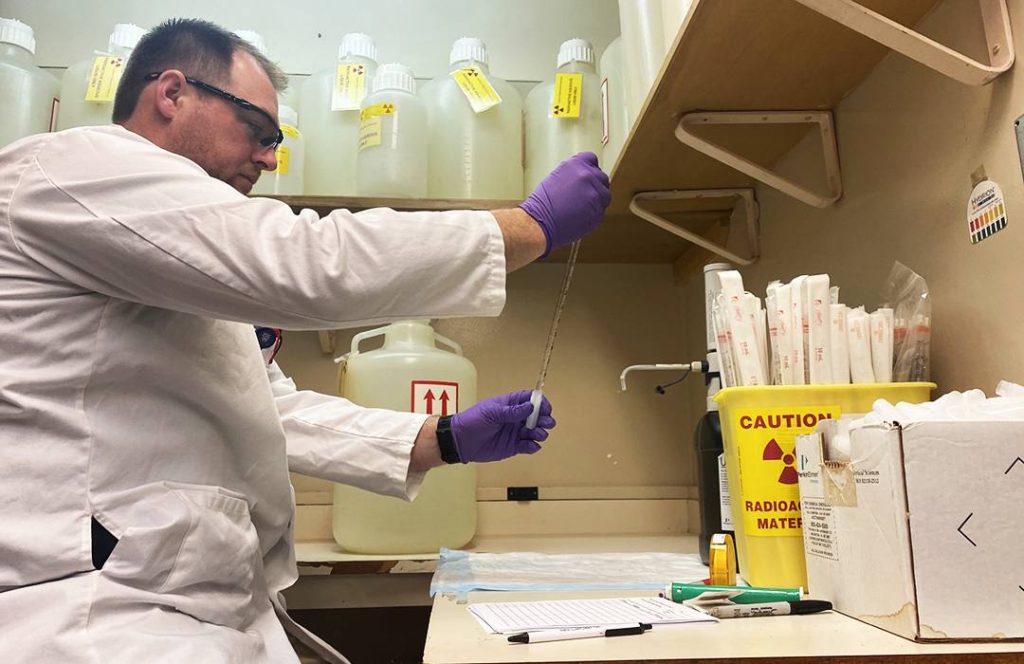

In addition to managing radioactive waste, the team neutralizes or stabilizes flammable, corrosive, highly toxic and reactive chemicals so that they can be safely disposed of.

Radioactive waste is separated into solid and aqueous, or fluid, waste. Solid waste — such as personal protective equipment or vials — is boxed up and stored at a safe and secure location on the outskirts of Rochester. Once radioactivity has decayed to safe levels — which takes 100 to 600 days — Gladkowski's team ships the solid items to Schwinefus' team for burning, while liquid waste can safely be added to the sewer.

"At that point, the radioactive materials activity is less than background radiation sources, like the sun," Gladkowski says.

He adds that Mayo is proud to handle almost all of its radioactive waste internally.

"It's an awesome cost saving, rather than sending it off to a vendor," he says.

The process for other hazardous chemicals is a bit more elaborate. They are collected in 55-gallon drums, and the team uses sodium sesquicarbonate — a form of baking soda — to create a safe pH level before flushing the liquid down the sewer. The process is highly regulated and done in collaboration with the city of Rochester and the Waste Water Treatment Plant.

If Gladkowski's team can't process a particular liquid, it gets stored in secured barrels and shipped to a vendor once a quarter.

While his team includes only seven members, Gladkowski says everyone is highly cross-trained and can perform any job at a moment's notice.

"It's a blessing to have the people I'm with. They're the hard workers. I'm just the encourager. They get the job done with a great attitude," he says.

Gladkowski also appreciates having Mayo Clinic values as a guidepost for his team's work.

"When we can live out Mayo's values and provide that to our colleagues, and they see that reflected in our work, I think that changes their day," he says.

Be part of the mission, become a waste champion

Tweite, Schwinefus and Gladkowski agree that the single biggest factor to successful waste management is educated staff who make smart decisions.

"Ultimately, it comes to anyone who has something to dispose of," Gladkowski says.

They encourage Mayo staff to join the Waste Champion Program in Rochester. Waste champions receive news and updates on waste and recycling operations at Mayo to share with their teams and encourage colleagues to help Mayo grow its environmentally sustainable and cost-effective waste management practices.

If your department or unit hasn't had an opportunity to work with Mayo's waste management team in Rochester, you can contact Angie Dalenberg, operations manager, to discuss options.

Learn more on the Waste Management and Recycling intranet page.

HELPFUL LINKS

- Explore Mayo Clinic.

- Learn more about Mayo Clinic's Transplant Center.

- Request an appointment.